![]()

UFIP Factory Tour

The UFIP factory is located in the small town of Pistoia about 30 minutes outside of Florence.

It is a quaint, pretty little town in the heart of Tuscany. We decided to visit at the urging of

our friend Andrea who is an endorser. Andrea made the call and set everything up for us with

a gentleman who was ever so charming and delightful - Mr. Luigi Tronci. Luigi greeted us early in

the morning and we were excited to learn that they would be casting that morning.

The front entry of the factory - a UFIP museum of sorts

The only thing Charlie Watts loves more than Savile Row suits is China cymbals - apparently he really loved this UFIP china.

One of the vaults

The machine shop floor

The library and R&D room

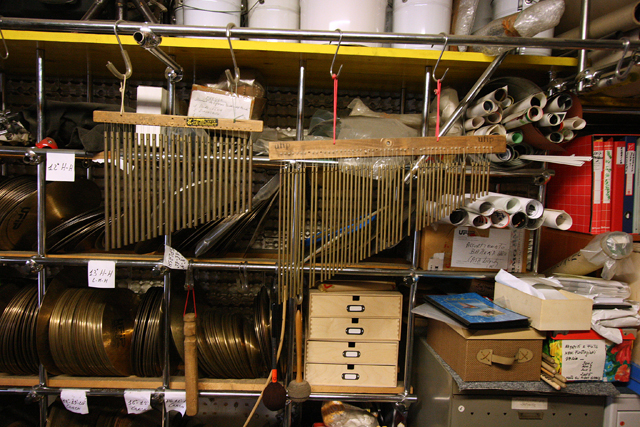

Some vintage UFIP wind chimes

UFIP cymbal production

Luigi gave us a very good tour and I took as many notes as I could. Hopefull I have everything right! UFIP cymbals are created using the B20 formula. They are the only cymbals I know of that are made using the rotocasting method. Pictured here is some raw material with cymbals in various states of ccompletion.

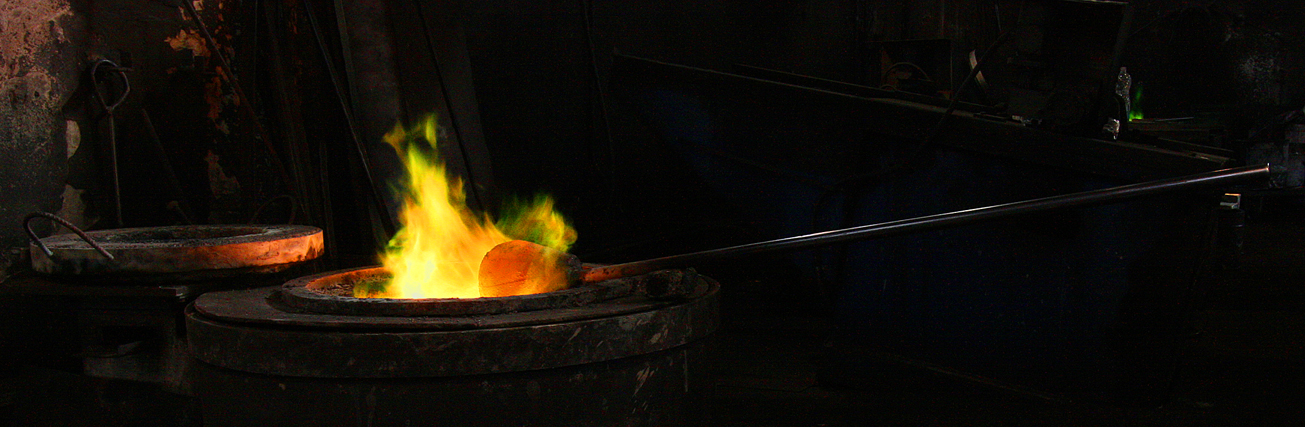

The casting room - cool, I mean hot huh?

This is one of the melting pots / furnaces. Rejected and broken cymbals are recycled.

The green flame is not embellished in any way -

this is how is actually looks!

The ladle and molten metal ready for pouring

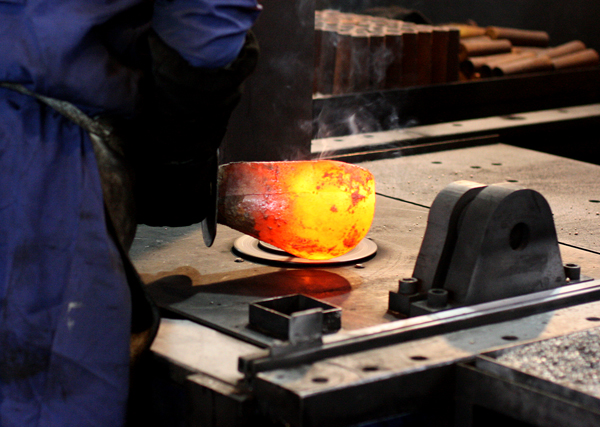

The rotocasting method involves a mold that spins as the molten metal is poured into the mold.

Here the artisan is seen preparing the mold with a compound that prevents the metal from adhering to the mold.

Moving to pour the molten metal into the mold....

The pour takes a steady hand

Several molds are filled at one time. There is a different mold for each type / size of cymbal.

Retired molds sitting outside the factory

Roto molds used in current production

We were very fortunate to see the casting process as it happens only two or three times a week.

A rack of raw castings fresh from the mold

More raw castings. You can see the casting branch in the centre of the disc.

TRaw castings - some with the casting branch removed, some waiting to be drilled.

Removing the centre casting

branch and drilling the hole

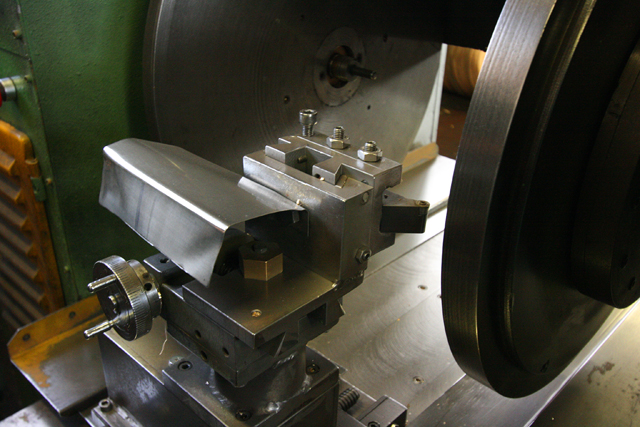

A close up of one of the lathes