![]()

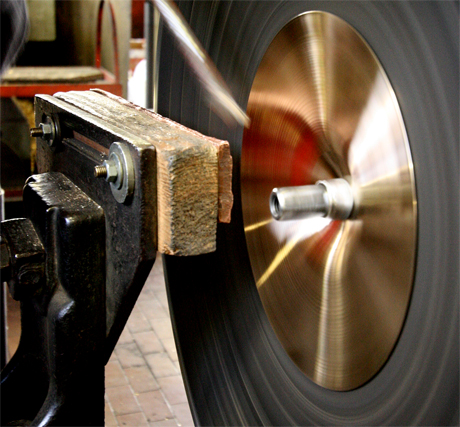

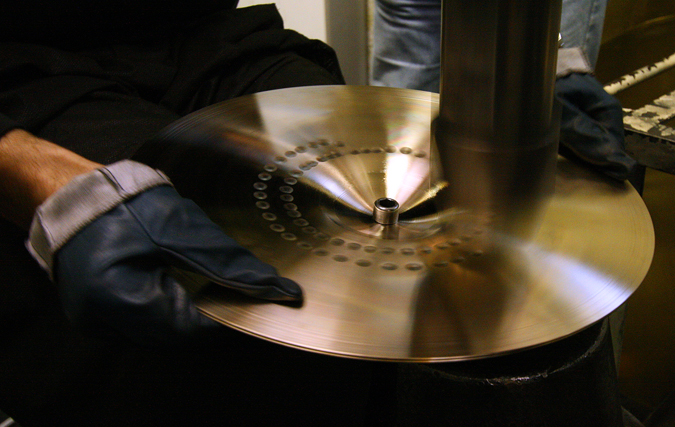

The lathing process begins with the cymbal blank

being bolted to the lathee

The cymbal is then turned down until it is approx.

the desired thickness and weight.

After the intial lathing process the cymbal is weighed.

If the target weight of the cymbal is not correct, the cymbal is put back for further lathing. The artisans who perform the lathing are skilled at shaving very fine amounts of material from the cymbal.

Weighing again..close!

A close up of the lathing

Luigi says "Perfect!"

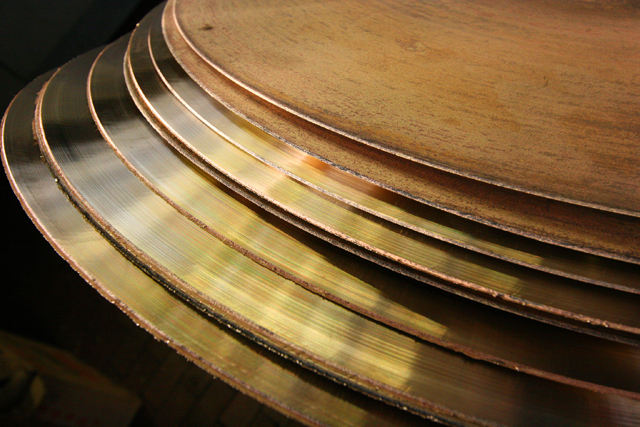

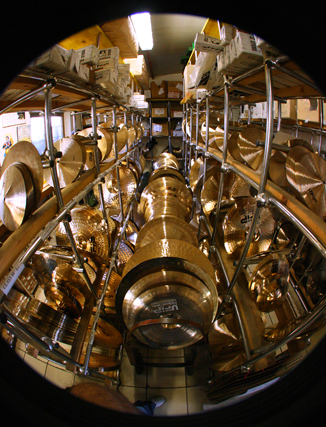

Lathed cymbals waiting to be edged

A stack of completed splashes

Hammering

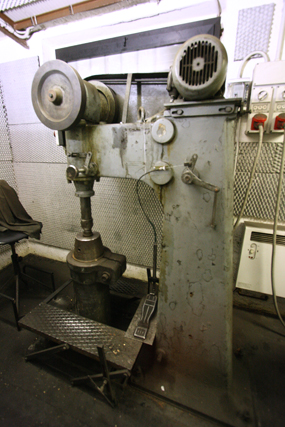

One of the machines used

in the hammeirng process

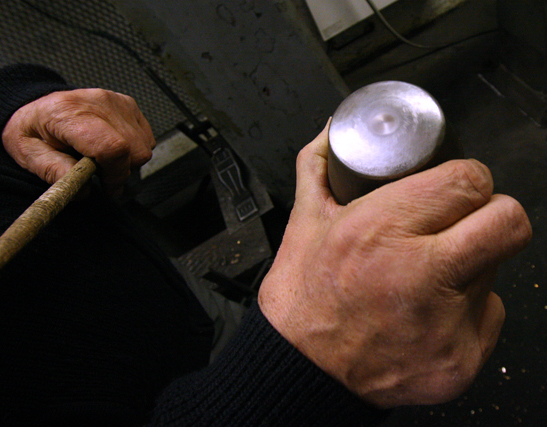

A hammer for the pneumatic hammering machine

Hammering machines are used widely in the industry, however there is a difference between automatic hammering and manual operation of these machines. Manual hammering using a pnuematic machine is far more practical given the amount of energy it takes to hammer a cymbal using a traditional hammer. I would say it takes just as much skil - if not more, to hammer a cymbal using a pnuematic/mechanical machine.

UFIP still does some hammering by hand.

Luigi demonstrating the sound of a partially completed cymbal

The weight of the cymbal is recorded on the underside of the bell

Stacks of fresh cymbals ready for shipping

A second vault

The company built a special soundproof testing room designed specifically for testing cymbals.

The shipping area

Ready for shipment!

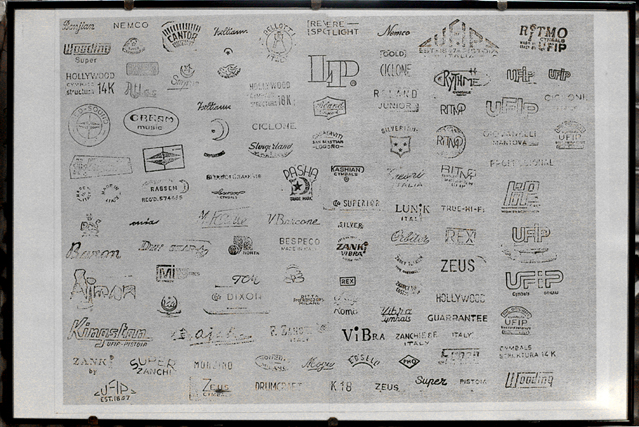

What I didn't realize before this visit was that UFIP has a very long history in the music business, and have made signature products for many famous brands. These are some of the trademarks that UFIP has made products for. See anything familair?

Seeing that we were impressed with UFIP's list of clients Luigi takes us upstairs to the archive room...

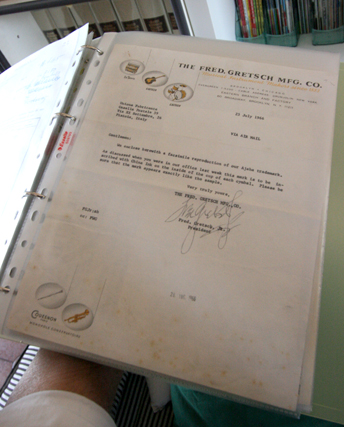

..and shows us purchase orders from Gretsch...

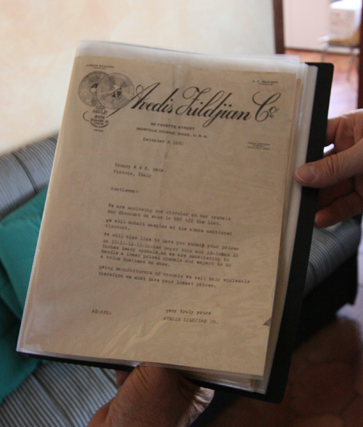

...letters from Zildjian...

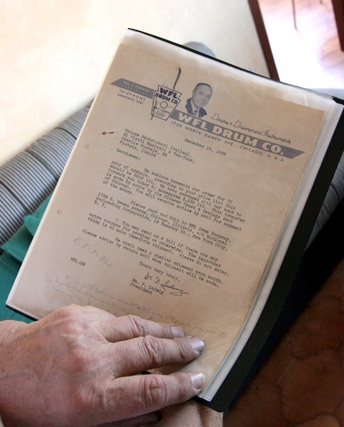

...and Ludwig!

An historic collection of some of the many instruments UFIP has created over the years

Need more cowbell? This one was designed especially for a famous percussionist - it was HUGE!

At one time UFIP created organ pipes

A set of fold out tuned discs.

an old set of bell castings

Luigi demonstrates some special symphonic gongs

Luigi was a very king host and very genrous with his time.

On a personal note, In many ways he reminded me of my Uncle Eric.

Luigi was kind enough to sit for an impromptu portrait.

Paul and I would very much like to thank Mr. Luigi Tronci and the great crew at UFIP

for their time and hospitality. It was a truly wonderful experience to witness the

creation of fine UFIP cymbals!

www.ufip.it

...on the road again...